產品標籤

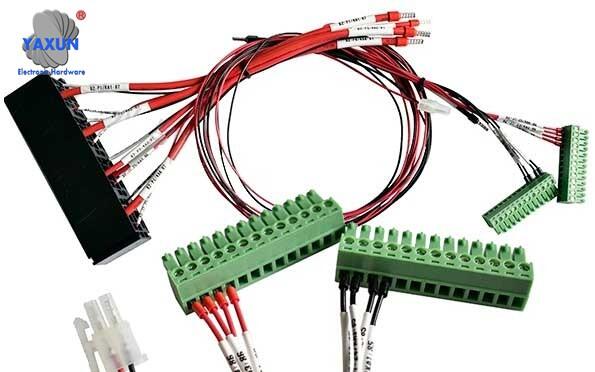

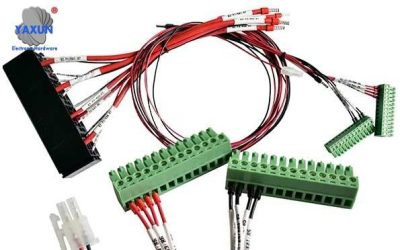

自動化機器人輔助線束組

製造機器人線束的流程通常包括以下步驟:

設計與規劃: 設計佈局, 根據機器人的需要和功能要求來確定線束的連接方式和電氣特性. 考慮電線截面積等因素, 長度, 顏色編碼和導線數量.

材料準備: 選用優質電線, 連接器, 適用於機器人應用的保護套和其他配件. 確保材料符合相關行業標準和規範.

根據您的圖紙或樣品要求定制的機器人安全帶.

金屬絲: UL1015, UL1007;

連接器: 管狀末端KT, 春季;

應用程序字段: 掃地機器人, 機械手臂機器人, 工業機器人, ETC。;

姓名: 機器人線束; 加工技術: 鉚, 組裝和成型;

根據客戶需求進行定制: 線束長度, 規格, 顏色, ETC。;

線束外部: 熱縮管;

金屬絲: UL1015, UL1007;

耐壓: 直流300V, 10 毫秒;

連接器: 管狀末端KT, 春季;

導通電阻: ≤2歐姆;

防水等級: IP67級;

絕緣電阻: ≥10megohm;

插拔循環: ≥5000次;

鹽噴霧測試: ≥48小時;

應用區域: 掃地機器人, 機械手臂機器人, 工業機器人, ETC.

機器人線束線束拖鏈電纜主要適用於頻繁移動和彎曲的場合. 因為更多普通電纜應該有: 高靈活性, 抗油, 較淺的防水性, 耐水性, 紫外線阻力, 極好的天氣抵抗力, 低溫抗性, 戴阻力, 以及承受重型機械外力的能力. 該電纜的加速度比普通柔性電纜更快,彎曲阻力更強.

機器人線束具有諸如高扭轉阻力之類的特徵. 它巧妙地在彎曲的機器人臂之間伸道,並且可以承受大量彎曲, 這大大增加了設備的使用壽命.

產品認證: UL, 工控機620, IP67級, 抵達, ROHS2.0, 醫學科學與技術研究所

公司榮譽及資質: 國家高新技術企業, UL, 工控機620, ISO9001, ISO14000, ISO13485, IATF16949, ETC.

機器人接線線束是指用於連接機器人各個部分和組件的電纜和佈線安全系統. 它包括多條電線, 連接器, 防護套和其他用於傳輸電源的配件, 信號和數據以實現機器人運動, 控制與溝通.

製造機器人線束的流程通常包括以下步驟:

設計與規劃: 設計佈局, 根據機器人的需要和功能要求來確定線束的連接方式和電氣特性. 考慮電線截面積等因素, 長度, 顏色編碼和導線數量.

材料準備: 選用優質電線, 連接器, 適用於機器人應用的保護套和其他配件. 確保材料符合相關行業標準和規範.

電線處理: 根據設計要求, 電線被剝皮, 切割和焊接. 確保電線末端具有良好的電氣接觸和電線隔熱材料.

連接器組件: 將電線插入連接器, 並組裝並修復連接器. 確保連接器和電線之間的良好接觸和穩定連接.

套筒安裝: 將防護套或鞘放在電線線束上,以提供物理保護和電磁屏蔽. 確保線束足夠靈活且耐磨損.

質量檢查: 嚴格的質量檢查和製造線束的測試, 包括電線連接性測試, 絕緣測試, 電參數測試, ETC. 確保線束符合設計要求和相關標準.

標籤和包裝: 標記和包裝佈線安全帶,以便於安裝和使用. 識別通常包括導體功能等信息, 顏色編碼, 和長度.

機器人線束安裝

機械手臂機器人線束

機器安全帶的功能包括:

複雜: 機器人線束通常包含大量電線和連接器,用於攜帶多種類型的電源, 信號和數據. 電線線束的佈局和連接需要根據機器人的結構和功能進行精確設計.

靈活性: 機器人安全帶必須具有靈活性和靈活性,以適應工作過程中機器人的運動和姿勢變化. 安全帶的設計和材料選擇需要考慮機器人的自由和工作空間要求.

耐用性: 機器人接線線束通常會在長時間內重複運動和振動, 因此,他們需要具有良好的耐用性和抵抗力來磨損. 選擇線束材料和連接方法必須能夠承受機器人工作環境的要求.

電磁屏蔽: 由於機器人操作期間可能存在電磁干擾, 接線線束需要具有一定的電磁屏蔽能力,以防止干擾信號傳輸和系統性能.

安全: 機器人佈線安全帶需要遵守相關的安全標準和監管要求,以確保線束的安全性. 接線線束需要進行嚴格的質量檢查和測試,以避免潛在的電氣問題和故障.

機器人線束的製造過程和特徵使其能夠提供可靠的功率, 信號和數據傳輸, 支持機器人的準確控制和有效操作. 精確的設計和製造過程確保線束的穩定性和可靠性, 從而提高機器人的工作效率和性能.

聯絡我們

等待您的電子郵件, 我們將在短時間內回覆您 12 小時提供您所需的有價值的信息.

English

English العربية

العربية Български

Български 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latīna

Latīna Latviešu valoda

Latviešu valoda Lëtzebuergesch

Lëtzebuergesch Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt