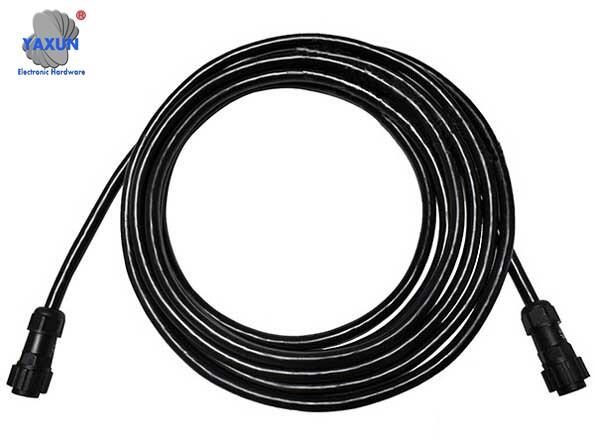

Customize industrial power Amphenol wire harnesses to your drawings or sample requirements.

Dây điện: UL;

Đầu nối: substrate terminals, đầu nối tròn (Amphenol), tubular terminals;

Ứng dụng: Internal and external wiring of industrial equipment;

Tên: Industrial power wiring harness–Amphenol wiring harness;

Công nghệ chế biến: tán đinh, cuộc họp;

Whether to process and customize: Customize the length, specification, color, vân vân. of the wire harness according to customer requirements;

Terminal pulling force: ≥22.3N

Đầu nối: substrate terminals, đầu nối tròn (Amphenol), tubular terminals;

Dây điện: UL

Chịu được điện áp: DC300V, 0.1 seconds;

Vật liệu chống điện: ≥5 megohms

Kháng chiến: ≤3 ohms;

Hiệu suất sản phẩm: Nhà sản xuất lựa chọn chất liệu cao cấp và sản phẩm có tính linh hoạt cao. It has the characteristics of acid and alkali resistance, oil resistance, moisture resistance, mildew resistance, flame retardant resistance, wear resistance, corrosion resistance, chất chống oxy hóa, không thấm nước, dustproof, UV resistance, vân vân.

Chứng nhận sản phẩm: UL, IPC620, VỚI TỚI, ROHS2.0, MASDS.

Danh hiệu và bằng cấp của công ty: Doanh nghiệp công nghệ cao quốc gia, UL, IPC620, ISO 9001, ISO14000, ISO13485, IATF16949, vân vân.

Industrial Power Supply Amphenol Wiring Harness

Industrial wiring harness is an electrical connection system used to connect multiple electronic components, sensors, switches and other electrical components together for signal transmission and power supply. It consists of a set of wires, cáp, and connectors that are insulated, protected, and bound to provide a safe, reliable electrical connection.

Industrial wire harnesses are widely used in modern manufacturing, especially in automobile manufacturing, aerospace, electronic equipment, mechanical equipment and other fields. They play a key role in these industries, connecting electronic components in various equipment and systems together to achieve signal transmission and power supply to ensure the normal operation of the equipment.

Power tool wiring harness

Industrial wire harnesses can be classified according to different classification standards. Here are some common classification methods:

Functional classification: According to the function of the wiring harness, it can be divided into power wiring harness, signal wiring harness and hybrid wiring harness. The power harness is mainly used to provide power supply, the signal harness is used to transmit control signals and data, and the hybrid harness has both power and signal transmission functions.

Application classification: According to the application fields of wire harnesses, they can be divided into automotive wire harnesses, aerospace wire harnesses, mechanical equipment wire harnesses, vân vân. Different industries have different requirements and standards for wire harnesses, so industry-specific needs need to be considered when designing and manufacturing wire harnesses.

Structural classification: According to the structure and wiring method of the wire harness, it can be divided into scattered wire harness and formed wire harness. Loose wire bundles are made up of individual wires and cables and are flexible in wiring for simpler applications. Formed wire harness refers to fixing wires and cables together through specific processes and equipment during the manufacturing process to form a predetermined shape and wiring structure, which is suitable for complex application scenarios.

Wire harness specifications: Wire harnesses can be divided into different types based on their size and specifications. The size of a wire harness depends on factors such as the number of wires and cables contained within it, its cross-sectional area, insulation materials, and other factors.

Environmental classification: According to the conditions and requirements of the wiring harness in the working environment, it can be divided into ordinary wiring harnesses and special wiring harnesses. The special wire harness has higher high temperature resistance, corrosion resistance, waterproof and dustproof properties, and is suitable for harsh working environments.

English

English العربية

العربية Български

Български 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latīna

Latīna Latviešu valoda

Latviešu valoda Lëtzebuergesch

Lëtzebuergesch Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt