Product Categories

Product Tags

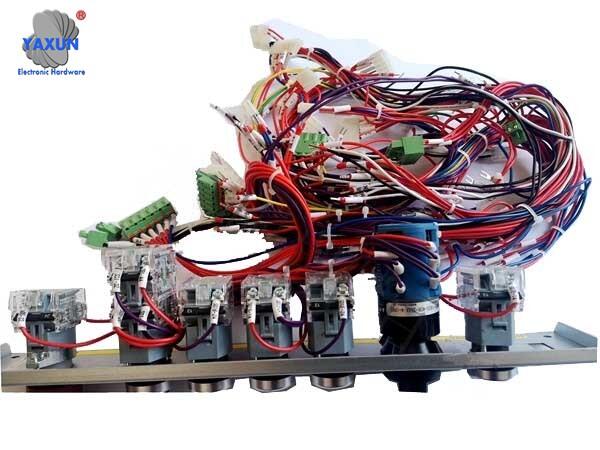

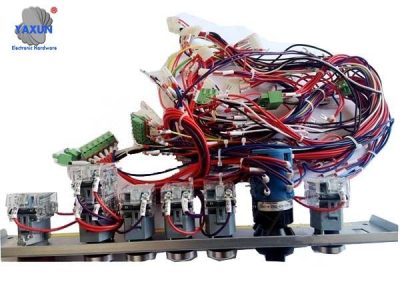

Electric Wheelchair Lift Wiring Harness ready made-up

This customized Electric Wheelchair Lift wire harness is used in the elevator light curtain system. The connectors are American MOLEX and the wires are national standard flexible cables. All materials comply with ROSH requirements and are processed in strict accordance with IPC620 standards. The product has excellent performance. Durable;

Customer case: Fujitec Elevator Elevator , Electric Wheelchair Lift Wiring Harness;

This customized Electric Wheelchair Lift wire harness is used in the elevator light curtain system. The connectors are American MOLEX and the wires are national standard flexible cables. All materials comply with ROSH requirements and are processed in strict accordance with IPC620 standards. The product has excellent performance. Durable;

Elevator wiring harness refers to the electrical wiring harness installed in the elevator system. The elevator wiring harness transmits power and signals from the elevator control system to various elevator components to realize the operation and control functions of the elevator.

Key features and functions of elevator wiring harnesses include:

1. Safety performance: Elevator wiring harness needs to comply with relevant safety standards and regulatory requirements to ensure the safe operation of the elevator. The wiring harness needs to have fire protection, protection and anti-interference capabilities to prevent the impact of electrical faults and electromagnetic interference on the elevator system.

2. Durability: The elevator wiring harness needs to have good durability and be able to withstand the vibration and impact caused by the long-term operation and frequent use of the elevator.

3. High temperature tolerance: The internal temperature of the elevator machine room is usually high, and the elevator wiring harness needs to have good high temperature tolerance and be able to work normally in a high temperature environment.

4. Standardized connectors: Elevator wiring harnesses usually use standardized connectors to ensure compatibility with various elevator components and facilitate installation and maintenance.

5. Adapt to different elevator types: Elevator wiring harnesses need to be designed and manufactured according to different elevator types and specifications to meet the requirements of different elevator systems.

The design and manufacturing of elevator wiring harnesses need to strictly follow the standards and specifications of the elevator industry to ensure their safety and reliability. Elevator wiring harnesses are typically designed and manufactured by elevator engineers and professional manufacturers to meet the special requirements and performance needs of the elevator system.

Electric Wheelchair Lift - Elevator Wiring Harness

Main features of elevator wiring harness

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية Български

Български 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latīna

Latīna Latviešu valoda

Latviešu valoda Lëtzebuergesch

Lëtzebuergesch Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt