제품 카테고리

- 의료 진단 케이블 5

- 온도 센서 프로브 0

- 맞춤형 배선 하니스 21

- 사출 금형 제조 7

- 전자 스위치 공급업체 9

- 커넥터 및 케이블 12

- 전원 플러그 제조업체 8

제품 태그

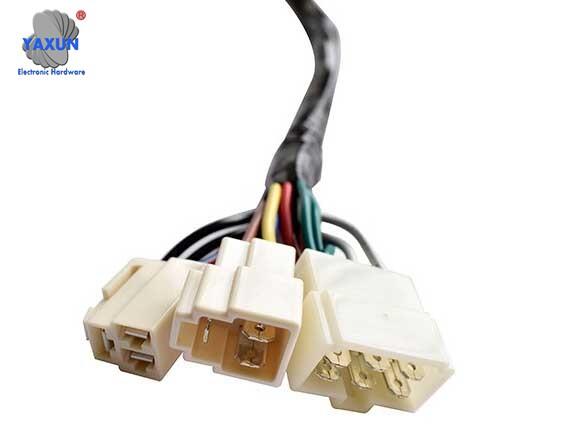

엔지니어링 기계 맞춤화 / 도면 또는 샘플 요구 사항에 따른 굴삭기 에어컨 배선 하니스.

케이블: QVR;

Connectors: direct plug terminals, blade terminals;

Application: industrial air conditioning;

Name: Engineering machinery air conditioning wiring harness;

Processing technology: riveting, assembly;

Whether to process and customize: Customize the length, specification, color, 등. of the wire harness according to customer requirements;

Application areas: engineering machinery air conditioning;

Voltage: DC300V 0.1 초;

Insulation resistance: 5 megaohms (최저한의);

On-resistance: 3 ohms (최고);

엔지니어링 기계 에어컨 배선 하네스 |

Excavator Air conditioning wiring harness |

직선형 플러그 블레이드 단자 배선 하니스 |

Product performance: The manufacturer selects high-quality materials and the product is highly flexible. It is acid and alkali resistant, oil resistant, moisture-proof, mildew-proof, flame-retardant, abrasion-resistant, corrosion-resistant, antioxidant, waterproof, dust-proof, and UV-resistant.

Product certification: IPC620, IP67, REACH, ROHS2.0, MASDS.

Company honors and qualifications: National high-tech enterprise, UL certified factory E497026, IPC620, ISO9001, ISO14000, ISO13485, IATF16949, 등.

The air conditioning wiring harness is used to connect the wires and electrical components of the vehicle’s air conditioning system to transmit signals and power. Air conditioning wiring harness usually includes power cords, sensor circuit lines, control system lines, working power supply, 등. They vary in color, specification and sequence and need to be designed and configured according to the specific vehicle and air conditioning system.

Air conditioning wiring harness generally needs to have the following characteristics:

1. High temperature resistance, moisture resistance and environmental protection: Air conditioning wiring harnesses often need to operate in air conditioning indoor environments with high temperatures and high humidity. 그러므로, it needs to have good high temperature resistance and moisture resistance and be able to operate stably for a long time.

2. Wear resistance and durability: Due to the small interior space of the vehicle, the wiring location of the wiring harness needs to take performance and space factors into consideration. 게다가, wire harnesses are often affected by adverse factors such as extrusion, which requires good wear resistance and durability.

3. Safety and reliability: The wiring and fixation methods of the wiring harness need to have high safety and reliability to ensure the driving safety of the vehicle.

The color and wiring method of the air conditioning wiring harness also need to be determined according to the model and manufacturer. Under normal circumstances, common electrical wiring harness colors are black, 하얀색, red, yellow, purple, blue and other colors, which need to be adjusted according to the wiring harness design and the space size and arrangement inside the vehicle.

저희에게 연락하십시오

이메일을 기다리고 있습니다, 우리는 당신에게 답장을 드리겠습니다 12 필요한 귀중한 정보가 필요한 시간.

English

English العربية

العربية Български

Български 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latīna

Latīna Latviešu valoda

Latviešu valoda Lëtzebuergesch

Lëtzebuergesch Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt