catégories de produits

Mots clés du produit

Messages récents

VE / Faisceau de câblage haute tension HT pour packs de batteries

VE / Faisceau de câbles haute tension HT Les conducteurs peuvent être divisés en conducteurs unipolaires et conducteurs multipolaires en fonction des caractéristiques du processus.. La différence est que les fils multiconducteurs sont constitués de plusieurs fils monoconducteurs.. En substance, les paramètres de performance électrique et les paramètres de taille structurelle de chaque fil unipolaire ne sont pas différents de ceux des conducteurs unipolaires. Si le câble multiconducteur est utilisé pour la transmission du signal, des mesures de blindage distinctes doivent être prises pour garantir que le signal n'est pas perdu.

VE / HV High voltage wiring harness range: Power battery PACK, energy storage battery PACK, telecom base station energy storage PACK.

High voltage wiring harness features:

Ensure a tight crimp on the wire harness with perfect crimp points.

Meet the pulling force requirements, safe and reliable.

Low temperature rise and high consistency.

Connecteurs et faisceaux de câbles haute tension

Classification of high voltage wires:

Conductors can be divided into single-core conductors and multi-core conductors according to process characteristics. La différence est que les fils multiconducteurs sont constitués de plusieurs fils monoconducteurs.. En substance, les paramètres de performance électrique et les paramètres de taille structurelle de chaque fil unipolaire ne sont pas différents de ceux des conducteurs unipolaires. Si le câble multiconducteur est utilisé pour la transmission du signal, des mesures de blindage distinctes doivent être prises pour garantir que le signal n'est pas perdu.

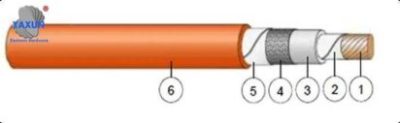

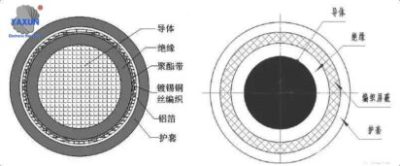

Figure-Multi-core shielded high-voltage cable

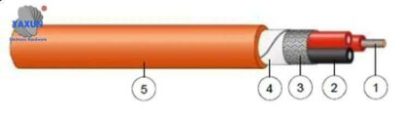

Figure-Single-core shielded high-voltage cable

Single core shielded high voltage cable

Single core unshielded high voltage cable

High-voltage conductors can also be divided into unshielded conductors and shielded conductors according to whether they have a shielding layer.

In addition to the four combinations of single-core shielded wires, single-core unshielded high-voltage wires, multi-core shielded high-voltage wires, and multi-core unshielded high-voltage wires, high-voltage wires can also be classified according to the following characteristics.

The composition of high-voltage wires:

Dissect the high-voltage wire from outside to inside, and you can see the following structural diagram.

High-voltage conductors are composed of secondary sheath (also called outer insulation), aluminum foil, shielding braid, inner insulation and core wire (conductor).

For industry standards, please refer to “QC-T1037 Automotive Industry Standard for High-voltage Cables for Road Vehicles” and “TCAS 356-2019 for High-voltage Cables for New Energy Vehicles”.

Some high-voltage conductors have a layer of tape between the shield and secondary sheath. The purpose of the wrapping tape is to facilitate the stripping of the insulation layer when producing crimped terminals. A material similar to non-woven fabric is wrapped around the wire and plays a certain isolation role.

The main structural size parameters of high-voltage conductors also revolve around these layers of materials, including the outer diameter of the secondary sheath, the diameter of the inner insulation layer, the diameter of the conductor, the diameter of a single copper wire, the number of copper wires, etc..

The function of high-voltage wire insulation layer:

(1) Insulation: Prevent the core wire from contacting other external conductors, causing a short circuit.

(2) Protect the core wire: prevent the internal wire core from being abraded by liquid and external devices.

(3) IP protection: including dustproof, étanche, and touch-proof (human body protection).

(4) Parts arrangement: Provide a certain degree of flexibility for the high-voltage wire harness to facilitate the arrangement of the high-voltage wire harness on the vehicle body.

(5) Anti-scratch, flame retardant, etc.. play special roles in weather resistance and reliability.

Anatomy of high voltage cable

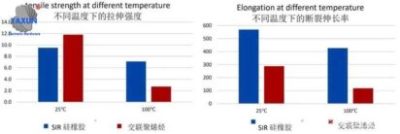

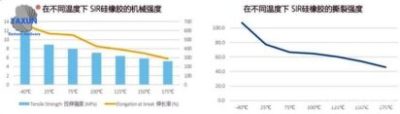

Figure – Tensile strength and breaking elongation of SIR silicone rubber cable at different temperatures

Figure – Mechanical strength and tear strength of SIR silicone rubber cable at different temperature

High-voltage wire insulation layer material properties:

Unlike low-voltage wires that only have an outer insulation layer, high-voltage wires have two layers of insulation, both inner and outer. The outer insulation layer is also often referred to as secondary sheathing. The materials for manufacturing the inner and outer insulation layers generally include XLPO (cross-linked polyolefin), SIR (caoutchouc en silicone) and TPE (élastomère thermoplastique).

Combining the characteristics comparison table of the above three materials, we can draw the differences between the three materials at the application level:

XLPO has a wide range of applications, and the parts in contact with the motor have a weak service life. TPE materials are mostly suitable for large-sized wires and communication wires.

In addition to the above characteristics, SIR silicone rubber also has good sealing properties. Under high temperature and high pressure, the deformation amount is small, and it is suitable for occasions that require high temperature resistance, small installation space, and small bending radius. As an insulating layer material for high-voltage wires in electric vehicles, it is perfect.

The function of high-voltage wire shielding layer:

High-voltage cables for electric vehicles bear higher voltages (rated voltage up to 600V), larger currents (rated current up to 600A), and strong electromagnetic radiation. Although high-voltage wires themselves do not produce large electromagnetic interference, the coupling voltage and coupling current of the wires basically come from the terminals connected to the wires, c'est, high-voltage electrical appliances.

Electromagnetic interference is concentrated at both ends of the wire, c'est, at the crimping point of the terminal. Donc, most of the current high-voltage conductors are designed with shielding structures to resist electromagnetic interference. It adopts a coaxial structure and utilizes the joint action of the inner conductor and the outer conductor (shielding layer). The magnetic field within the wire is distributed in concentric circles, while the electric field is directed from the inner conductor to the outer conductor, making the external electromagnetic field around the cable zero. That is to say, it shields electromagnetic radiation and eliminates the coupling voltage and coupling current in this area.

In the electromagnetic compatibility (EMC) test of the entire vehicle, high-voltage wiring harness parts need to meet the requirements of ISO 14572, with transfer impedance ≤31mΩ/m and shielding attenuation ≥70dB to meet the EMC requirements of the entire vehicle.

The high-voltage wire shielding layer is divided into a shielding wire braided layer and an aluminum foil layer. The conventional shielding layer structures are:

①Only shielding wire braid

② Shielding wire braid (close to the inner insulation layer) + aluminum foil layer (close to the outer insulation layer)

③Three states: aluminum foil layer (close to the inner insulation layer) + shielding wire braiding layer (close to the outer insulation layer).

Bien sûr, some high-voltage conductors use braided mesh, aluminum tubes, or a combination of the two to directly cover the outer layer of the cable to provide EMC protection for the conductors.

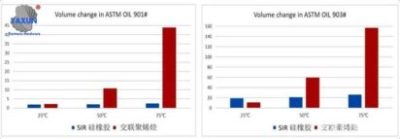

Volume change rate of oil resistance test of SIR silicone rubber cable in different oil products

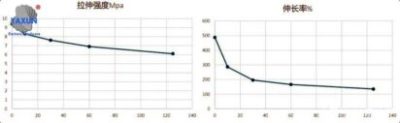

Performance of SIR silicone rubber cable in 200 ℃, 3000 hours aging test

High-voltage cables are composed of two different forms of shielding layers

Contactez-nous

En attente de votre email, nous vous répondrons dans les 12 heures avec des informations précieuses dont vous aviez besoin.

English

English العربية

العربية Български

Български 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latīna

Latīna Latviešu valoda

Latviešu valoda Lëtzebuergesch

Lëtzebuergesch Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt