κατηγορίες προϊόντων

Ετικέτες προϊόντων

Αυτοματοποίηση σετ καλωδίωσης με υποβοηθούμενη από ρομπότ

Η ροή της διαδικασίας για την παραγωγή καλωδίων ρομπότ συνήθως περιλαμβάνει τα παρακάτω βήματα:

Σχεδιασμός και προγραμματισμός: Σχεδιάστε τη διάταξη, Μέθοδοι σύνδεσης και ηλεκτρικά χαρακτηριστικά της πλεξούδας καλωδίωσης ανάλογα με τις ανάγκες και τις λειτουργικές απαιτήσεις του ρομπότ. Εξετάστε παράγοντες όπως η περιοχή διατομής καλωδίων, μήκος, χρωματική κωδικοποίηση και αριθμό αγωγών.

Προετοιμασία υλικού: Επιλέξτε καλώδια υψηλής ποιότητας, συνδετήρες, Προστατευτικά μανίκια και άλλα αξεσουάρ κατάλληλα για ρομποτικές εφαρμογές. Βεβαιωθείτε ότι τα υλικά συμμορφώνονται με τα σχετικά πρότυπα και προδιαγραφές της βιομηχανίας.

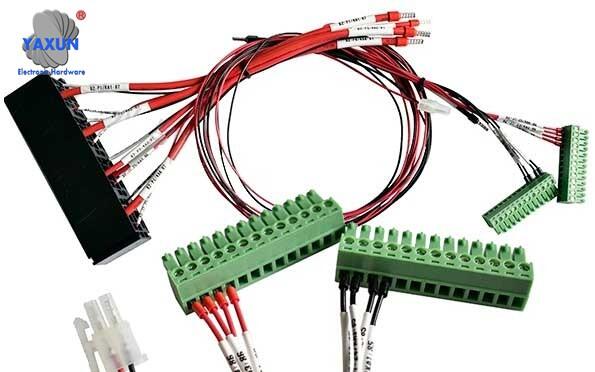

Customized robot harness according to your drawing or sample requirements.

Σύρμα: UL1015, UL1007;

Συνδετήρας: tubular terminal KT, spring terminal;

Application fields: sweeping robots, mechanical arm robots, industrial robots, και τα λοιπά.;

Name: Robot wire harness; Processing technology: riveting, assembly and molding;

Customized according to customer needs: wire harness length, specifications, color, και τα λοιπά.;

Wire harness exterior: heat shrink tubing;

Σύρμα: UL1015, UL1007;

Withstand voltage: DC300V, 10 milliseconds;

Συνδετήρας: tubular terminal KT, spring terminal;

On-resistance: ≤2 ohms;

Waterproof grade: IP67;

Insulation resistance: ≥10 megohm;

Plug and unplug cycle: ≥5000 times;

Salt spray test: ≥48 hours;

Application areas: sweeping robots, mechanical arm robots, industrial robots, και τα λοιπά.

Robot wire harness drag chain cables are mainly suitable for occasions with frequent movement and bending. Because more ordinary cables should have: high flexibility, oil resistance, shallow water resistance, moisture resistance, UV resistance, excellent weather resistance, low temperature resistance, wear resistance, and the ability to withstand heavy mechanical external forces. The cable has faster acceleration and stronger bending resistance than ordinary flexible cables.

The robot wire harness has characteristics such as high torsion resistance. It is cleverly routed between the curved robotic arms and can withstand a large number of bends, which greatly increases the service life of the equipment.

Product certification: Ul, IPC620, IP67, REACH, ROHS2.0, MASDS

Company honors and qualifications: National High-tech Enterprise, Ul, IPC620, ISO9001, ISO14000, ISO13485, IATF16949, και τα λοιπά.

Robot wiring harness refers to the cable and wiring harness system used to connect various parts and components of the robot. It includes multiple wires, συνδετήρες, protective sleeves and other accessories used to transmit power, signals and data to achieve robot movement, control and communication.

Η ροή της διαδικασίας για την παραγωγή καλωδίων ρομπότ συνήθως περιλαμβάνει τα παρακάτω βήματα:

Σχεδιασμός και προγραμματισμός: Σχεδιάστε τη διάταξη, Μέθοδοι σύνδεσης και ηλεκτρικά χαρακτηριστικά της πλεξούδας καλωδίωσης ανάλογα με τις ανάγκες και τις λειτουργικές απαιτήσεις του ρομπότ. Εξετάστε παράγοντες όπως η περιοχή διατομής καλωδίων, μήκος, χρωματική κωδικοποίηση και αριθμό αγωγών.

Προετοιμασία υλικού: Επιλέξτε καλώδια υψηλής ποιότητας, συνδετήρες, Προστατευτικά μανίκια και άλλα αξεσουάρ κατάλληλα για ρομποτικές εφαρμογές. Βεβαιωθείτε ότι τα υλικά συμμορφώνονται με τα σχετικά πρότυπα και προδιαγραφές της βιομηχανίας.

Wire processing: According to the design requirements, the wires are peeled, cut and soldered. Make sure the wire ends have good electrical contact and wire insulation.

Connector assembly: Insert the wire into the connector, and assemble and fix the connector. Ensure good contact and stable connection between connector and wire.

Sleeving Installation: Place protective sleeves or sheaths over wire harnesses to provide physical protection and electromagnetic shielding of the wires. Make sure the wire harness is sufficiently flexible and abrasion-resistant.

Quality inspection: Strict quality inspection and testing of manufactured wire harnesses, including wire connectivity testing, insulation testing, electrical parameter testing, και τα λοιπά. Ensure that the wiring harness meets design requirements and relevant standards.

Labeling and packaging: Label and package the wiring harness for easy installation and use. Identification usually includes information such as conductor function, color coding, and length.

Εγκατάσταση καλωδίωσης ρομπότ

Μηχανική καλωδίωση ρομπότ βραχίονα

Features of robotic harnesses include:

Complexity: Robotic wiring harnesses often contain large numbers of wires and connectors used to carry multiple types of power, signals and data. The layout and connection of the wire harness need to be precisely designed based on the structure and function of the robot.

Flexibility: The robot harness needs to be flexible and flexible enough to adapt to the movement and posture changes of the robot during work. The design and material selection of the harness need to take into account the robot’s freedom and workspace requirements.

Αντοχή: Robotic wiring harnesses are often subjected to repeated motion and vibration over long periods of time, so they need to have good durability and resistance to wear and tear. The selection of wire harness materials and connection methods must be able to withstand the requirements of the robot’s working environment.

Electromagnetic shielding: Since electromagnetic interference may exist during robot operation, the wiring harness needs to have a certain electromagnetic shielding capability to prevent interference from affecting signal transmission and system performance.

Ασφάλεια: Robot wiring harnesses need to comply with relevant safety standards and regulatory requirements to ensure the safety of the wiring harness. Wiring harnesses need to undergo rigorous quality inspection and testing to avoid potential electrical problems and failures.

The manufacturing process and characteristics of the robot harness enable it to provide reliable power, signal and data transmission, supporting accurate control and efficient operation of the robot. Precise design and manufacturing processes ensure the stability and reliability of the wire harness, thereby improving the robot’s work efficiency and performance.

Επικοινωνήστε μαζί μας

Αναμονή για το email σας, θα σας απαντήσουμε εντός 12 ώρες με πολύτιμες πληροφορίες που χρειαζόσουν.

English

English العربية

العربية Български

Български 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latīna

Latīna Latviešu valoda

Latviešu valoda Lëtzebuergesch

Lëtzebuergesch Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt